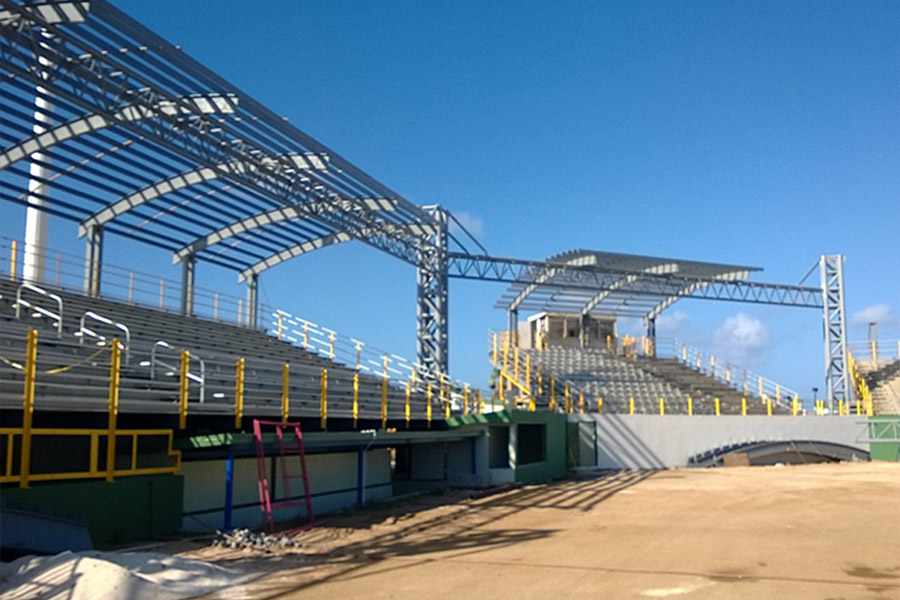

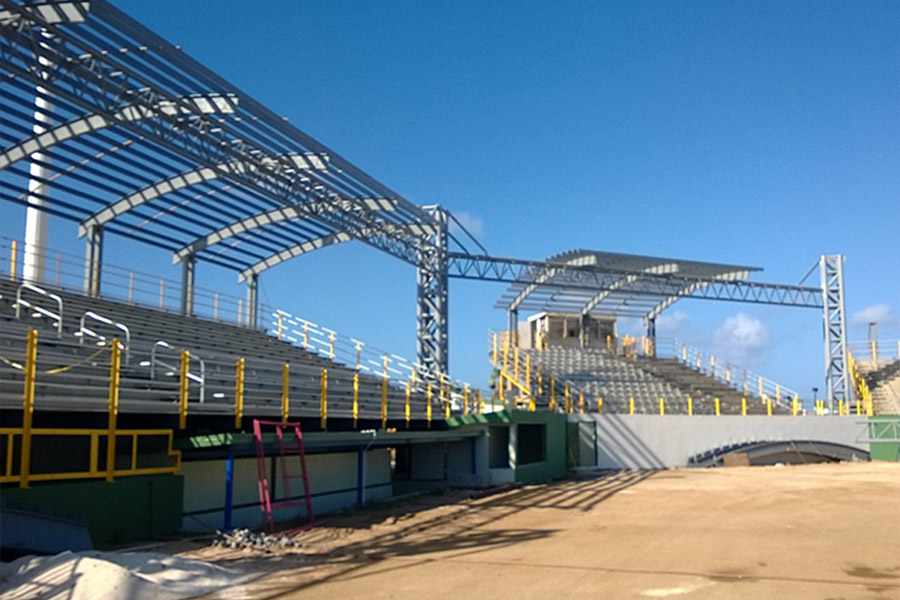

Project address:Aruba

Bay spacing: 127m

Eave height: 9.14m

Steel amount: 62.357ton

Frame type: Pipe truss structure

Aruba stadium, the use of special-shaped curved steel beams, processing difficulty into geometric growth, near the playground is not added columns, the use of space truss beams as support, the design is very bold, but very beautiful. Although the amount and area of steel used is not large, it has achieved a new breakthrough in processing difficulty.

Aruba Stadium is known for its groundbreaking steel structure design. At its core, it uses three-dimensional curved and twisted steel beams to create a streamlined roof, precisely controlling the curvature radius and spatial positioning of each steel member. The main body uses the long-span space tube truss system to replace the traditional column, and adopts Q345B high-strength steel and full penetration welding technology to achieve the cantilever structure with a span of 35 meters.In the construction, CNC arc bending equipment is used to complete the processing of double curved steel beams, and cast steel joints are used to connect the trusses and special-shaped members to ensure the stability of the structure under complex loads. The roof system innovatively incorporates purlins and prestressed tensioning technology to form a self-balancing system with only 320 tons of steel used. Its pillarless design of galvanized cladding makes the building like a suspended art installation, setting a new industry benchmark for the processing accuracy of special-shaped steel structures.

To bring high quality products and services to thousands of households